Defense Systems

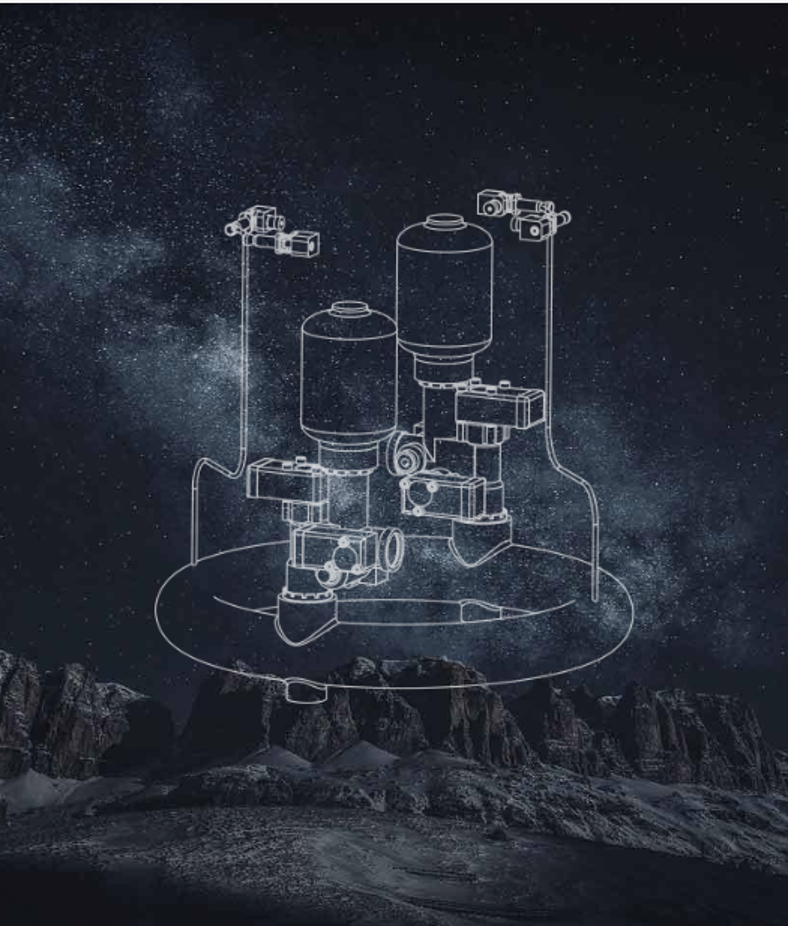

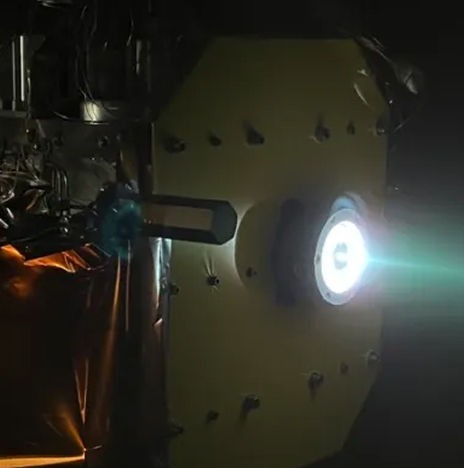

Our propulsion systems deliver precise, long-duration thrust for orienting, positioning and steering missile interceptors and/or space operation payloads, including extremely fast and accurate high thrust levels required for hypersonic applications. Our controllable solid propulsion technology emulates the operational performance found in liquid and cold-gas systems. This capability enables higher precision, improved reliability, faster response, safer operation, and better affordability.

Propulsion Technology

We design, manufacture, and test electric propulsion elements for small spacecraft, from discrete components to integrated propulsion modules and full spacecraft buses.

Our next-gen solid propulsion technology meets the stringent requirements for Department of Defense, Department of Energy, NASA, and commercial space systems. Our propulsion products perform under extreme conditions to substantially enhance performance for applications that include: missile defense interceptors and kill vehicles; strategic, tactical and hypersonic missiles, and reentry systems; and civil, commercial and military space launch systems and payloads.

Next-Gen vs Conventional:

Solid and Liquid Propulsion

- Conventional Systems: These systems burn propellant continuously, impacting how and when the propulsive energy can be used. This diminishes operation time as compared to other types of propulsion systems of the same size and weight.

- Our Next-Gen Solid Systems: We don’t have these limitations. We regulate energy output with throttling cycles and extinguishment and ignition.

- Conventional Systems: Liquid propulsion systems require special precautions for shipping, handling, and sorting the hypergolic and toxic mono- or bipropellant, driving high user costs.

- Our Next-Gen Solid Systems: Our systems are safe, and do not require these extensive measures, lowering cost throughout the systems life cycle.