Ground Launch Support

Fittings

Our design team couldn’t find off-the-shelf quick disconnect fittings that were able to meet the stringent standards of aerospace. Everything was either custom, with 26-week lead times, or too much of a mass penalty because they weren’t designed with flight-side efficiency in mind. So we designed our own, blank sheet to a prototype in client’s hands within eight weeks. Then, we standardized them to work across all of the industry, from launch vehicles, to orbital servicing, to lunar landers.

These fittings are the connection between the vehicle and the ground fluid systems, useful for loading first stages, second stages, payload fairings, or even the payloads themselves.

- We offer standard “full port” line sizes from 1/4″ up to 2″ in the following configurations:

- Slip fittings – No internal poppet checking mechanisms.

- Single checking fittings – Automatic checking mechanism on only one side (either ground or vehicle).

- Double-checking fittings – Internal automatic checking mechanism on the ground side and on the flight side that snap shut after disconnecting.

- Custom sizes up to 6” are available.

Fittings

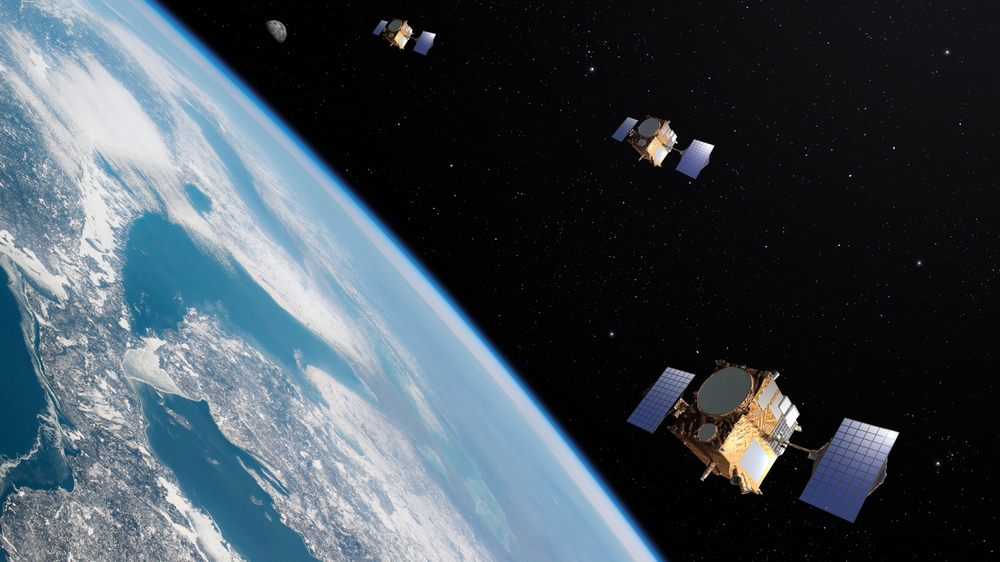

- Orbital Refueling Fittings are used for remote fluid resupply operations between space vehicles.

- Our orbital fittings are modularly designed to be compatible with our QD fitting line. QD flight-side fittings mate to our Orbital Fittings, helping drive standards from launch site to orbit.

- Latching fittings are available that allow the fittings themselves to react pressurization forces and anchors them during fluids transfer. This feature saves mass and complexity on mating plates.

- We offer “full port” line sizes from 1/4″ up to 2″ in double-checking configuration.

- We also develop custom fittings – contact us to learn more.

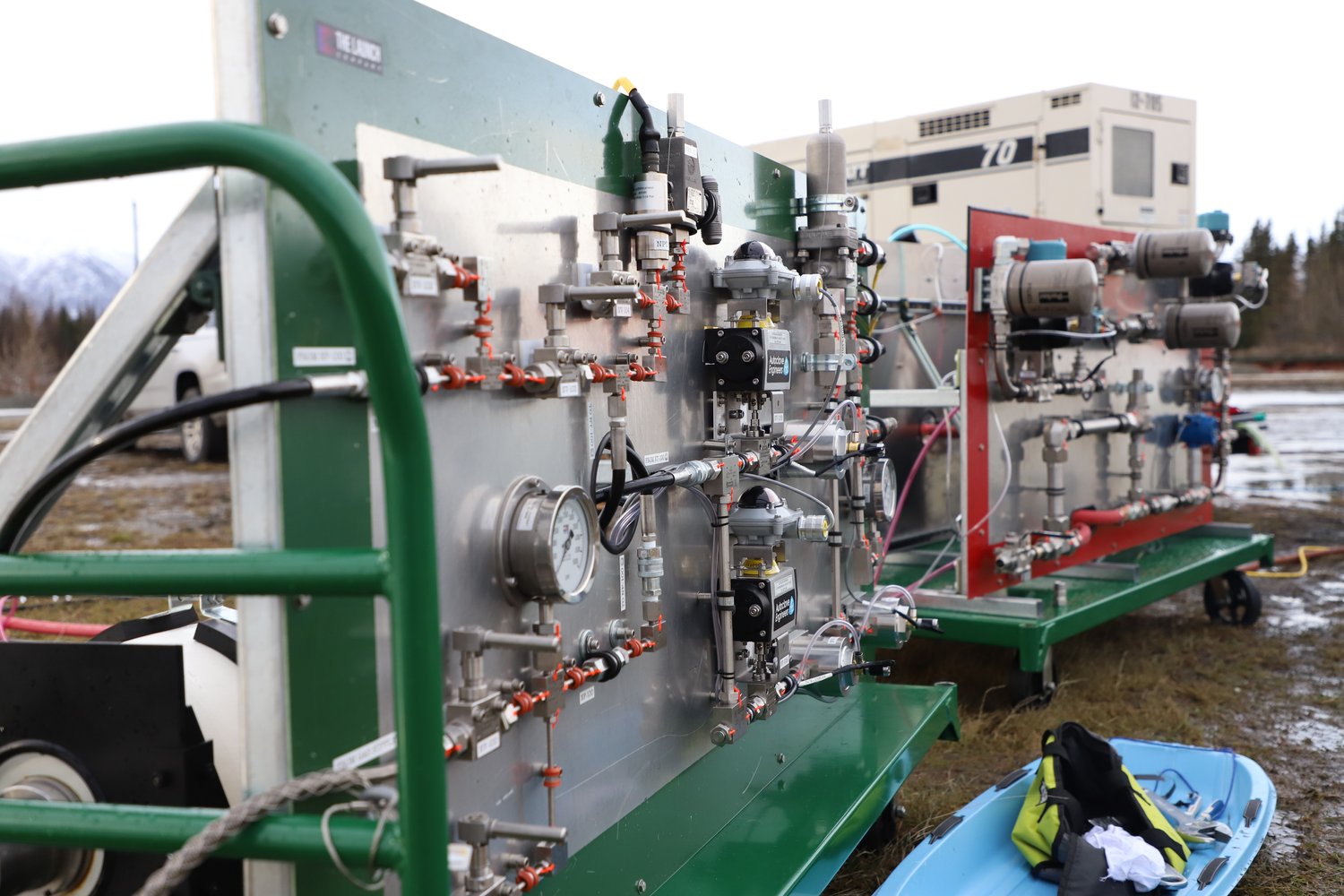

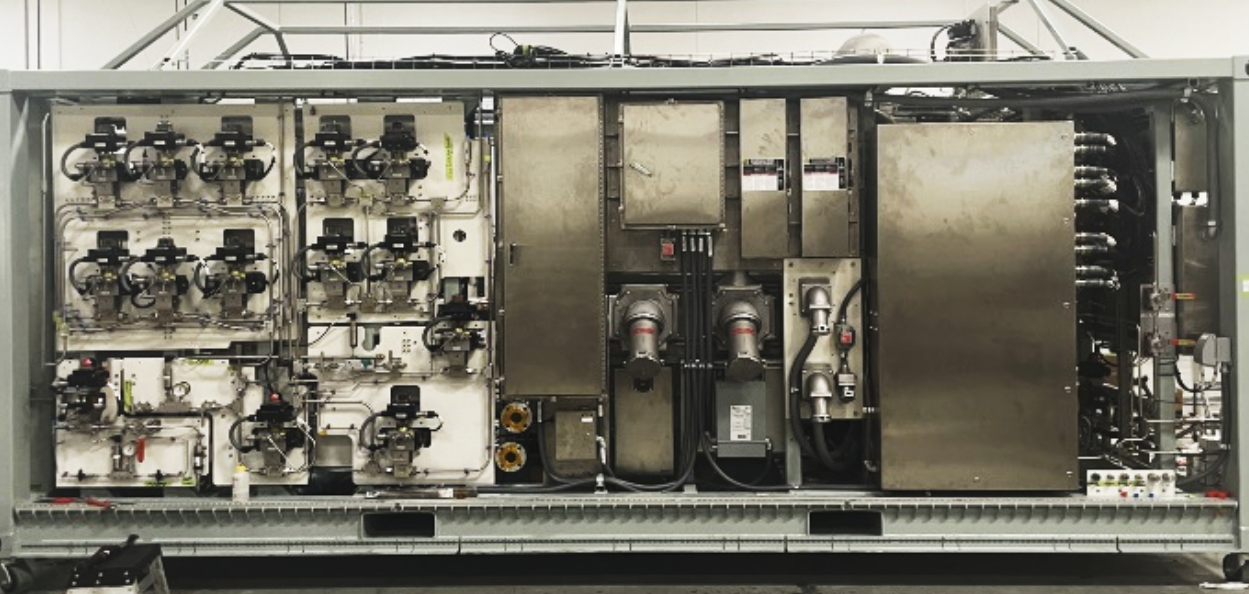

Custom Ground Support

Equipment for Test & Launch

We have worked with USAF, AFWERX, NewSpace leaders, and Spaceports to provide custom ground support equipment modules for test and launch.

Our team has designed and built fueling modules, oxidizer modules, sub-cooled oxidizer densification systems, and RP-1 or other hydrocarbon loading modules for conditioning and pump or inert gas based fuel transfer.

- Methane loading modules utilizing either pump, autogenous, or inert gas based fuel transfer.

- High-pressure helium loading and recovery modules

- Variable pressure nitrogen loading, purge, and pneumatic modules.

- Simulation hardware for test.

- A module is a self-contained piece of hardware that can be used for fueling aircraft, spacecraft, or launch vehicles. Handling inert gasses, or any other application you may have.

- Can be a shipping container.

- Standardized design to make them faster and more cost-effective.

- Capacity thing too – they can’t do this in-house.

- Launch Planning: From launch requirements to selecting your launch site and developing CONOPs, our team is here to guide you.

- Ground System Design: Fluid systems for land, sea, and air are our specialty. When it’s time to build your ground system, we partner with your internal technician team for fabrication.

- Procedure Development: We have extensive experience writing activation procedures to safely bring your launch systems online. We write all activation, qualification, test, and launch procedures.